World

AI Challenge propels real-world solutions and workforce skills

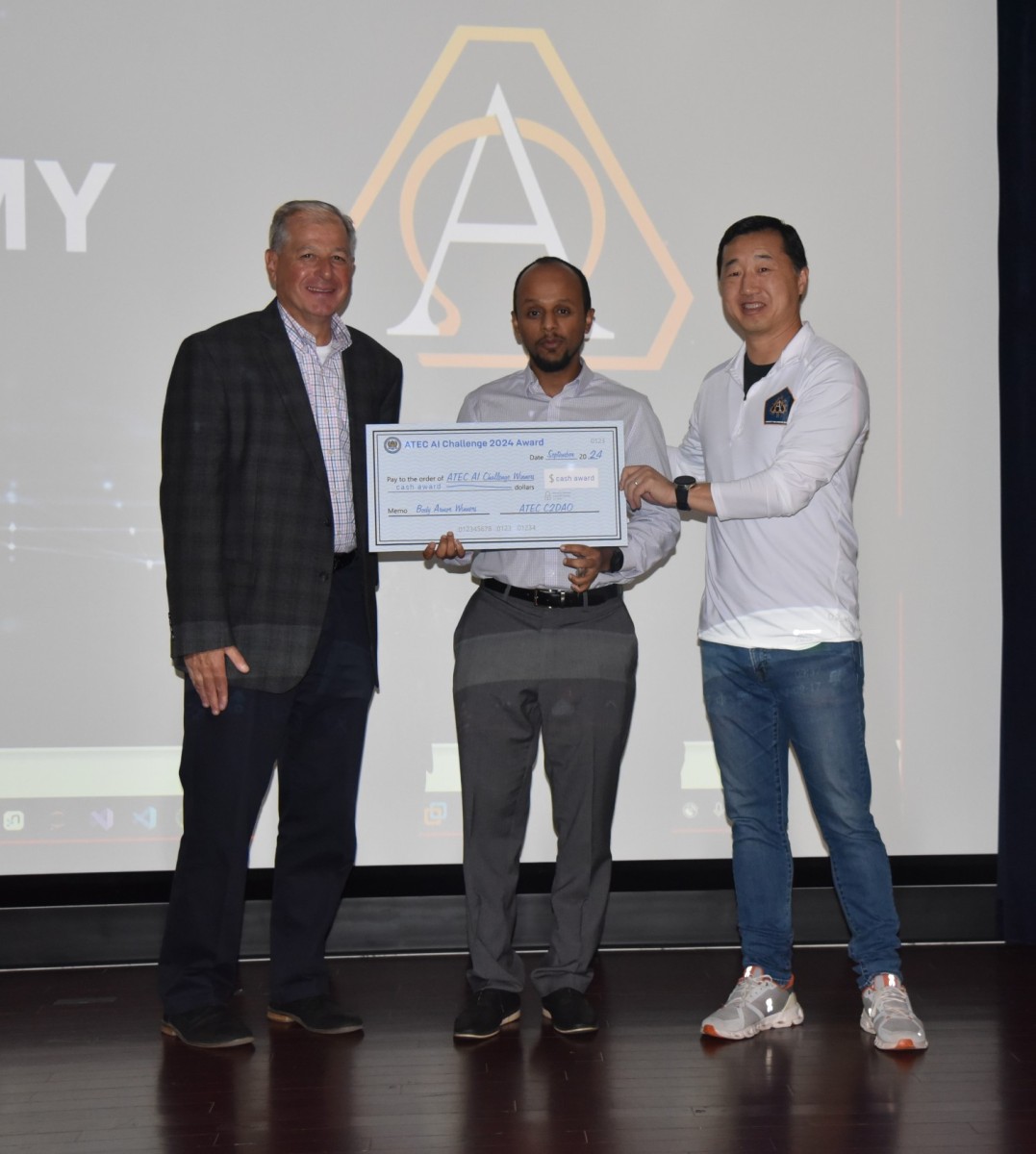

ABERDEEN PROVING GROUND, Md. – The U.S. Army Test and Evaluation Command crowned the winner of its second annual ATEC AI Challenge at its 3rd annual ATEC Data Summit on Sept. 17.

The purpose of the challenge was to canvas the ATEC workforce for opportunities to solve real-world problems with AI and machine learning solutions that had a high potential return on investment. Additionally, ATEC sought to learn how to validate test and evaluation procedures for AI-enabled systems by assessing the challenge submissions to determine the winner. In turn, ATEC will apply these lessons to improve how it tests and evaluates materiel systems that incorporate AI and machine learning.

This year’s AI challenge focused on how to improve analysis of flaws in soldier body armor plates, which is currently a manual process done by an analyst examining X-ray images. By leveraging AI algorithms, ATEC saw the potential to dramatically speed up this process, giving the analyst time back to investigate the root cause of any identified flaws.

X-ray image patch used in the competition. The image has a defect, which can be seen as the spot in the x-ray image of the body armor displayed in Figure 1. The goal of the AI was to determine if there is a defect in all x-ray images captured.

VIEW ORIGINAL

X-ray image patch used in the competition. The image has a defect, which can be seen as the spot in the x-ray image of the body armor displayed in Figure 1. The goal of the AI was to determine if there is a defect in all x-ray images captured.

VIEW ORIGINAL

X-ray image patch used in the competition. The image has a defect, which can be seen as the spot in the x-ray image of the body armor displayed in Figure 1. The goal of the AI was to determine if there is a defect in all x-ray images captured.

VIEW ORIGINAL

Ultimately, 29 teams and 153 participants from across the Department of Defense acquisition community entered the contest to develop a solution. The team judging criteria was based on a scoring metric that emphasized catching every body armor defect. This year’s winner was team “No To Destructive Testing,” from the U.S. Army Aberdeen Test Center.

Steven Shrewsbury, mechanical engineer and one of five members of the winning team, explained their contest submission that won the contest.

“We explored different AI models and ultimately chose the Vision Transformer, which is a cutting-edge model for image analysis,” he said.

Leveraging the Data Mesh

“The AI Challenge demonstrated the power of ATEC solving its own problems with ATEC’s data,” said Maj. David Niblick, military evaluator from the Analytics, Artificial Intelligence, and Digital Engineering Directorate within the U.S. Army Evaluation Center, an ATEC subordinate organization. “Teams from across the acquisition community leveraged the ATEC data mesh to provide an advanced and common computing environment to learn and put into action AI skills in a way that ATEC can bring to production to save significant time and money.”

Niblick said the ATEC data mesh is a cloud-based infrastructure to house all ATEC test and evaluation data. The data mesh integrates ATEC under a single IT umbrella and contains modern tooling and infrastructure to enable digital transformation.

However, “ultimately ATEC relies on champions to drive adoption of more efficient and effective methodologies,” he noted. “A phenomenal example of integration of champions and infrastructure is the 2024 AI Challenge.”

Notably, this year’s competition saw significant growth from its 2023 counterpart, which centered on improving data analysis of acoustical sensors for munitions testing at Yuma Proving Ground, or YPG. The winning solution is currently in use at YPG, saving the Army hundreds of man hours of work.

That competition was open only to the AAIDED, and as a result, only three teams participated. But by using the cloud-based infrastructure of the data mesh, AAIDED was able to expand the contest to a DoD-wide effort in 2024.

A Collaborative Environment

The ATEC Data Summit, now in its third year, proved to be the perfect venue to crown the winners. Data Summits are opportunities for engineers and scientists to come together for collaboration, idea sharing and dialogue regarding progress toward digital transformation within ATEC and across the Army. They originated from ATEC’s Command Chief Data and Analytics Officer Brian Kelly, who had the vision to digitally transform the ATEC test and evaluation community.

Mr. Young Bang, principal deputy assistant secretary of the Army for Acquisition, Logistics and Technology, or ASA(AL&T), presented the award to this year’s winning team, along with Mr. James Amato, ATEC’s Executive Technical Director.

Mr. Bang concluded by congratulating the team and stating his intent to have ASA(AL&T) partner with ATEC to expand the AI Challenge to wider participants and problem sets in future years.

.jpg)