Bussiness

Hillenbrand shifts focus to industrial manufacturing – Inside INdiana Business

Loading audio file, please wait.

An Iowa native, Kimberly Ryan started her career in 1989 as an accountant at Batesville Casket Co., but she didn’t stay in the post long.

Over the years, she worked in many roles for Batesville as well as in strategy, finance, operations and information technology positions for its then-parent, Hillenbrand Industries Inc., and other subsidiaries.

During much of that time, the company has been evolving. The big transformation began in 2008, when Batesville-based Hillenbrand and subsidiary Hill-Rom, a maker of hospital equipment, split into two publicly traded companies.

Ryan stayed with Hillenbrand. And in December 2021, she became president and CEO of the company. It has been a time of additional transition, with several acquisitions and the divestiture of Batesville Casket, where she got her start.

IBJ talked with Ryan about what Hillenbrand is today.

There have been quite a few changes at Hillenbrand over the past few years, including acquisitions and divestitures. What is Hillenbrand today?

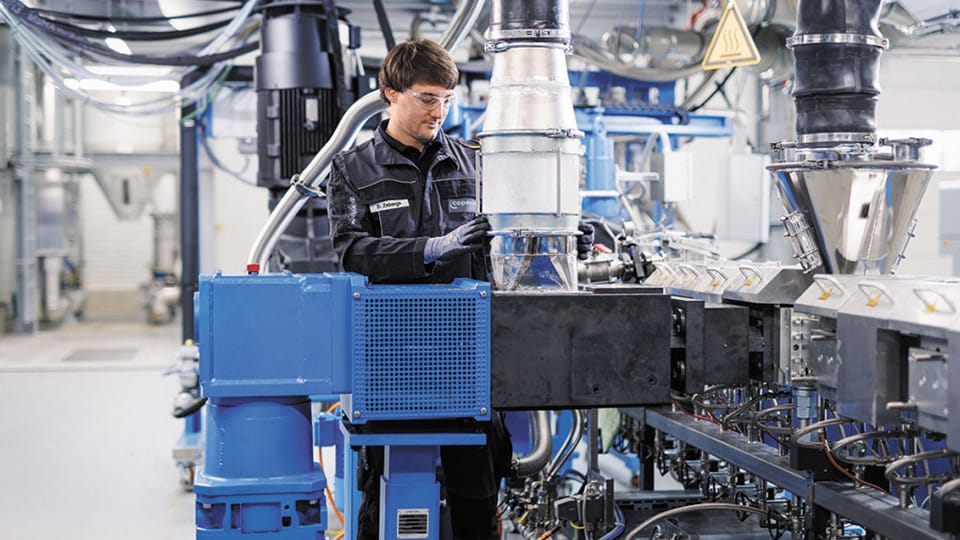

Since we transformed and spun out as a separate publicly held company in 2008, we’ve been focused on transforming ourselves away from our legacy company and into a new space. And our early acquisitions—starting in 2009 with the acquisition of K-Tron [International]—really started moving us towards the industrial space. … Over the last 16 years we have been able to evolve into a pure-play industrial company.

The latest evolution in our portfolio has us really focused on durable plastics, food recycling and advanced materials processing. We build the equipment and then we install it. We maintain it for its decades of life. We help modernize it over time.

We’re a company focused on new and growing end markets that serve growing secular trends in the world—a growing global middle class focused on sustainability, focused on new technologies and increasing complexity in the technologies that we use in our everyday life.

I think as consumers, we get very focused on the actual goods we receive. But what Hillenbrand does is develop the equipment that helps your customers manufacture products. Is that right?

Correct. So we’re selling processing equipment to the manufacturers of either the raw materials or the goods that we are purchasing as consumers. So when I look around my desk and I see all of these durable plastics with high fit and finish and I walk out to my kitchen and am eating processed foods or … I have a Beyond meat burger for lunch or I’m working out in the garage, all of those goods are produced on the types of machinery that we manufacture. But we don’t actually manufacture or sell any of that. We just do the processing equipment.

You mentioned durable plastics and recycling. How big of a change have you seen in what your customers are demanding in terms of figuring out ways to have a more circular economy?

I would divide your question into two.

What kind of change have I seen? In the area of durable plastics, let’s talk … about the virgin polymer side of the business. I would say that that has evolved dramatically. We as a manufacturer of equipment have to certify that we can manufacture that polymer at the right quality levels, at the right output levels, at the right performance levels.

[Plastic is] a very ubiquitous material. It can be easily changed in terms of its design. The science regarding these materials means that things that never used to be made of plastics can now be made of plastics. Some are impact resistant, some have high fit and finish, some have high heat tolerance, some have high ability in terms of strength and some feel just like leather. Each of those requires a different formulation. And so each of those requires different types of changes on your equipment to be able to process them.

On the sustainability side, there’s a lot of discussion around sustainability. It’s not just: Are you running recyclate? Or can you handle recyclate? It’s also: Is your equipment running efficiently? What does your equipment require in terms of the water you have to have and waste water that comes out of it and the energy it requires to run it? … We cannot be afraid of sustainability. We need to be running to it.

It seems like you are putting an increased emphasis on durable packaging for food.

I came into the role about 2 1/2 years ago—I was announced for the role three years ago. Since then, we have acquired a number of food companies. The processing equipment that is used—believe it or not—for food processing is very similar to processing equipment we use in the manufacturer of advanced materials like polymers. They’re just made out of different materials. So for instance, [food equipment] is made out of stainless steel as opposed to regular steel. They have different accessibility for cleanability, etc.

This was an end market that we moved into because the demands in this end market have been growing with a growing global middle class as people continue to focus on sustainable food sources or they continue to focus on manufacturing food out of materials that require a higher degree of processing. … These are things that are important to a new generation of consumers coming into the market.

You worked with Coca-Cola and the organization Net Impact on the Circular Plastics Case Competition for college students and professionals. What is that about?

This is something that we started as a part of our sustainability initiatives. We didn’t actually start it with Coke. We started it with Net Impact on our own. And it was an opportunity for us to tap into the next generation and thinking around how we might create a more circular economy.

These teams are literally from all over the world. They come into a case competition. So for those who are familiar with what an MBA case competition might look like, this is similar. We give the teams certain parameters. They have several weeks and months to come up with their recommendations. We take those recommendations, they present to a panel, we [narrow it down], and then … finalists come in and we select a winner who receives a cash prize.

And probably more importantly, it creates the types of connections into industries that can ultimately help [participants] perhaps bring this vision to life—as we saw with last year’s winner, who actually has taken their concept and turned that into a real product that is being manufactured in the marketplace today.

Coke heard about this a year ago and was very keen to get involved in it.

You started your career at Hillenbrand—or at a company that became part of Hillenbrand. Tell us the origin story.

I grew up in Iowa. My parents were educators. I also wanted to become an educator, and my parents advised me that I should move into a business type of environment. And so ultimately, I became an accountant, went to Iowa State University and moved to Batesville Casket Company as an accountant at the beginning of my career in 1989.

So I had an opportunity through Hillenbrand’s leadership development programs. I did accounting for about six years, and I love having a financial background. It’s very helpful in my career. But I also … had an opportunity to move into a wide variety of assignments and through all of our operating entities. I got a chance to be in the casket business for a number of years, ultimately got a chance to take a senior level position and then move over to our corporate headquarters and over to our health care business, back to our casket business, and then moved to our plastics business in Germany.

All of those moves were in pursuit of development of experiences that I might need to continue to be able to be a contributor at senior levels of the company. And I’m very grateful for that. And it’s still a part of what we do for leaders today.

When you came to the company, did you have any idea you would rise to be CEO?

Absolutely not. … There was a statistic that our [chief human resources officer] was sharing with me recently about how to coach young women into positions of greater responsibility. You have to keep in mind that … most women, when they see opportunities for advancement or changes in their career, unless they read the job description and they tick every box, they’re not going to apply. And that’s different for men. They see I have most of those skills and I will take the risk to move into a position.

I was very fortunate to have mentors who … would say: I think you should apply for X, or I want you to take on this responsibility, or I know you can do this and you should give this a try. And over time, your confidence builds. But it’s important that there are encouragers in the organization who help you kind of see those opportunities before you have all of your own chutzpah, as my grandma used to call it.

I never came here thinking I would be here 35 years. … It was to be a stop along my journey, but something captured me in the company, in the community, in the opportunities in the state of Indiana. … And I’ve been here now longer than I’ve not, and I’m thrilled to have had my children here, raised my children here and really given them what I believe is a great foundation in a great community with stability and professionalism and expectation for what they could do with their lives.

How do you try to ensure that those same opportunities are afforded to your employees?

Part of our operating model is very focused on talent development and succession planning. So I don’t care if you are a supervisor in accounting or on the shop floor or you are the CEO, we’re going to go through an exercise every year and we’re going to take a look at, we’re going to make sure that we’re reviewing employees and that we talk about strengths and opportunities for advancement.

And we’re going to look through key positions in our organization, and we’re going to make sure that we understand who in the organization is the next person who could—or the next five people who have the skill sets and the aspirations and the desire—to move into positions in the company. And then you have to make sure that you’re looking out for what are the experiences that I can give Mike or Bob or Sally or whoever to help them be successful in the next role that we could see them in.

You have been very involved in the community. Why is that important for you and for the company?

It’s critically important to be an active part of the community. You need to think about how you are going to help in creating a vibrancy that attracts people to want to work in the communities in which you operate. And whether that is Batesville or whether that’s in Cincinnati or whether that’s in Salina, Kansas, or Stuttgart, Germany, you need to be someone who is known in the community and someone that people respect in the community and would be proud to work for.

You don’t get that by just sitting along the sidelines. … Here in Batesville, there’s an internship type of program at the high school where high school students can opt in for coming a day, an afternoon or two a week, where they can sidecar with someone and work in their job and see what it’s like to work, to work in a company as opposed to school. And so my kids have participated in those programs and come over and work at the company.

We provide mentorship and training programs at community colleges.•

This article is part of IBJ’s annual Corporate 100 report. Check out more Corporate 100 content here.

Story Continues Below